Slit Tube Laminate

Art works provided by.

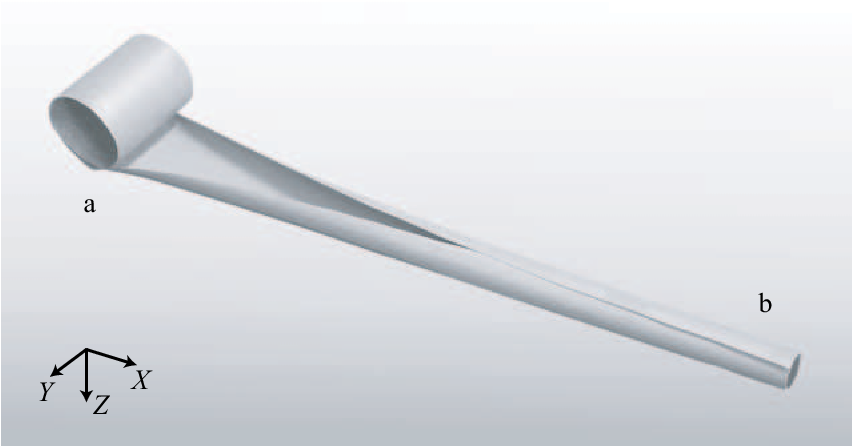

Slit tube laminate. 1 2 to 4 33 cutting depth. Bistable composite slit tubes bcsts are open section tubular structures that can be rolled up to stow and extended to deploy analogous to tape measures but are stable in both configurations without the need of a support structure. We can laminate adhesives to most plastic films with a wide variety of adhesives depending on the properties required. I placed the trimmed foam over a taut rope as described earlier.

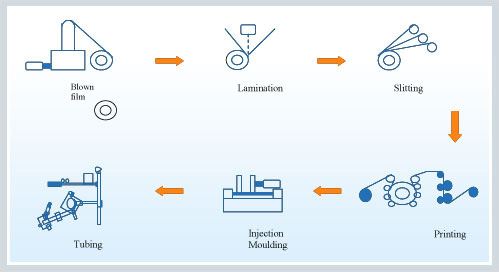

Problems getting those easy to lay click together laminate boards to fit properly. To create one continuous tube sections straight or curved can be joined to other sections. Shop and save on laminateslit. How laminate tubes are made.

To ensure that the adhesive lamination is meeting the required specifications we have an in house i mass sp 2000 peel adhesion tester for testing peel adhesion of all laminated products. The latest invisible side seam sealing technology combined with the right. Try here usa http. Here is the easiest way to lay them especially if working on your own.

They benefit from first class digital printing. Laminate tubes have undisputed aesthetic qualities. Pbl laminate tubes have several layers one of which is the evoh ethylene vinyl alcohol barrier layer to protect the tube s contents for maximum shelf life. Sleeves than travel to the mandreal.

The printed laminate is loaded where it is indexed trimmed wrapped and seamed. Once the laminate is slit to a desired size it is ready for printing. An extended state where there is transverse curvature but no longitudinal curvature and a coiled state where there is longitudinal curvature and minimal transverse curvature. As an alternative an all plastic evoh containing polyethylene structure is added.

0 to 3 32 product type. When made from particular layups of composite these structures have two stable states. Now the it takes complete shape of the tube. Blank laminate is loaded onto the printer and is than printed and slit.

Qdp can help you in determining what adhesive will work best for your application. Joining tube sections. Neck and shoulder are attached to the sleeve. The first helical tube laminate predicted to be bistable capable of producing an untwisted coil is located.